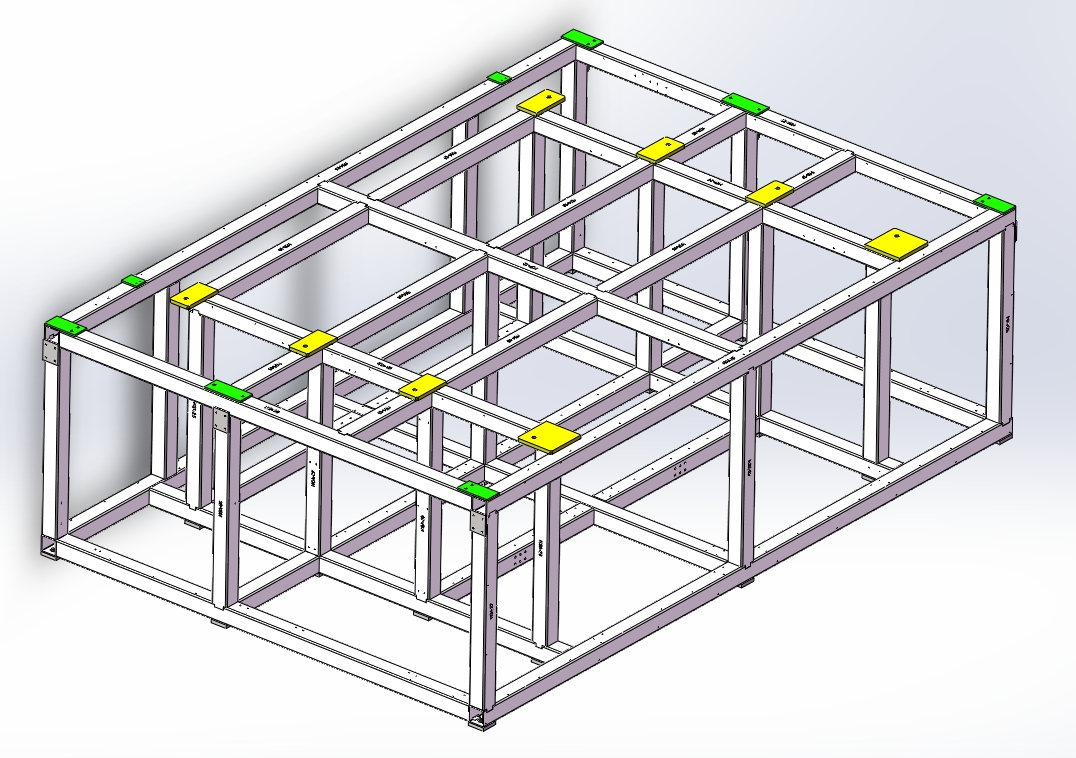

Fangtong rack

We have significant advantages in the manufacturing of large racks. Firstly, the workshop is equipped with aerial cranes, which greatly facilitates the lifting and assembly of large components, effectively improving work efficiency. At the same time, the workshop has a large oven that can meet special process requirements and ensure the quality and performance of the rack. It is worth mentioning that our workshop is as high as 8 meters and has four ovens. The maximum oven cavity reaches 11 * 3 * 4.5 meters, providing ample space for the production of large racks. We have outstanding performance in terms of product accuracy. The diagonal error of the large rack we manufacture is strictly controlled within plus or minus 2mm, which ensures the structural stability and overall quality of the rack with high precision. Moreover, the door gap spacing of the rack is precisely controlled within 2mm, which not only reflects our exquisite craftsmanship level, but also ensures the sealing and safety of the rack during use.

Production standards:

V158-3000-001-R01X. Before milling the lower gantry of the square frame, annealing treatment (combined with 3D files) is required according to the actual size of the frame;

Yellow welding block requires gantry milling: parallel to the foot cup plate, parallelism requirement: 0.15mm; Flatness requirement: 0.15mm; The height difference with the foot cup plate is 1359.0 ± 0.2mm;

Green welding blocks require gantry milling: flatness requirement: 0.15mm; Parallelism requirement with yellow solder block: 0.15mm; The height difference is 10.0 ± 0.1mm;

The yellow and green processing surfaces need to be preserved with anti rust coating oil. Anti rust oil: Kovinyl wash premer, model: PE-184 (national defense color)/thickness: 10um (reference value)

Identification: Yellow line circular hole processing: 4-m4 penetration;

Identification: Red line circular hole processing: 12-m16 through;

Identification: Green line circular hole processing: 8-m24 through;

Related products: